KOGA HDPE WALL

KOGA GRP WALL is a cladding system for walls and surfaces, which was developed to finish the visible part of subways and tunnels in an aesthetic way.

Features

Part of the system are cheek elements made of GRP (Glass-Reinforced Plastic) designed together with a base structure made of stainless steel. It is possible to combine shapes and colors on one facade, thanks to which we can get a unique architectural effect. Part of our delivery is Production-Technical Documentation and a laying plan, prepared based on the focus on construction. We cover professional design, production and implementation of the system directly on site.

GRP has excellent utility properties, namely non-absorption, frost resistance, color fastness due to resistance to UV radiation, high resistance to stress and dynamic load.

Any damage resulting from acts of vandalism (painting, graffiti) can be easily removed without damaging the outer surface. The system is designed to allow the possible replacement of seriously damaged elements, which can be replaced individually, without the need to dismantle a larger area than the damaged one.

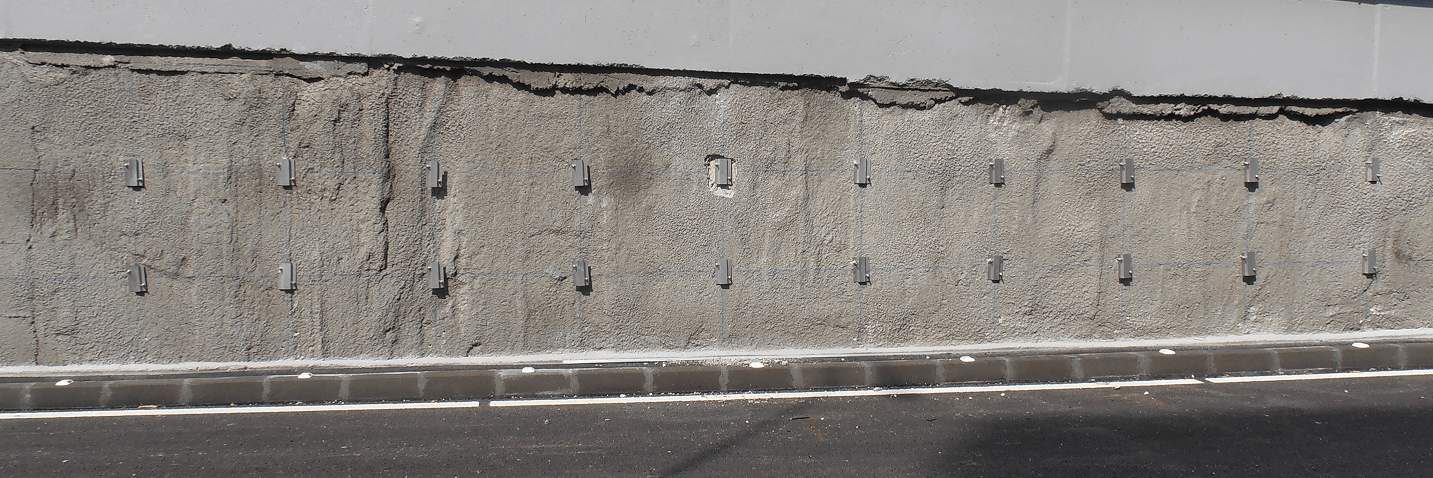

Underlying construction

An innovative base structure system was developed for assembly and installation, which is made of corrosion-resistant steel. The strength of the entire system was calculated taking into account the static and dynamic properties acting inside the operating tunnel. The substructure is designed in such a way that it is possible to rectify the fixed points and to level out surface and local depressions of the surface under the cladding system. The anchoring system is designed so that the mounting elements are not visible on the visible surface of the facial prefabs, which significantly improves the final aesthetic effect.

Thanks to this material design, it is possible to use the KOGA GRP WALL system in tunnels and underpasses with leaks towards the inside of the building, which are not visible and do not threaten the life of the entire system.

Advantages

- high aesthetic value of the finished work

- invisible connections

- maintenance-free system

- the possibility of rectification of the substructure, which eliminates the unevenness of the overlapped surface

- frost resistance thanks to the non-absorbent surface of individual panels

- color stability due to increased resistance to UV radiation

- the possibility of combining colors and shapes, which guarantees a unique final effect

- easy handling on the construction site, because one panel weighs approx. 5 kg

- quick installation on site

- high supply capacity

- long service life of the substructure even with local seepage of subsurface water due to the use of corrosion-resistant steel class A2 (DIN1.43) or A4 (DIN1.44)